Applies To:

Show Versions

Platform Maintenance

About maintaining the platform

The VIPRION® 4400 Series platform contains several components that you can replace individually without exchanging the entire system. This platform contains these replaceable components:

- AC power supply

- DC power supply

- Fan tray

- Storage drive assembly

Note: Applies only to the B4300 blade with hard disk drive (HDD).

- Front bezel (with LCD component)

- Blades

About AC power supplies

The VIPRION® 4400 Series platform supports up to four hot swappable power supplies. These power supplies can operate in one of two modes: 120V and 220V, depending on the power source to which the power supplies are connected.

The platform supports both symmetric and asymmetric power redundancy. Symmetric redundancy (2 * N) requires an even number of power supplies, with half supplied by one power feed and half by another. If one power feed fails, the system is unaffected because the remaining supplies are sufficient for the entire load. With asymmetric redundancy (n + 1), it is not possible to split the supplies evenly between the power feeds. As a result, if one power feed fails, the entire system can go down. In either type of redundancy, if a single power supply fails, the system is unaffected by the loss of a single supply.

A power supply partially removed from the platform

Installing an AC power supply

About DC power supplies

The VIPRION® 4400 Series platform supports up to four hot swappable DC power supplies.

You can install a DC power supply without powering down the system, provided that there are still enough power supplies to equal one less than the number of running blades. For example, if the chassis has three blades, you can replace a power supply, as long as the platform has at least two power supplies operating during the replacement process.

The platform supports both symmetric and asymmetric power redundancy. Symmetric redundancy (2 * N) requires an even number of power supplies, with half supplied by one power feed and half by another. If one power feed fails, the system is unaffected because the remaining supplies are sufficient for the entire load. With asymmetric redundancy (n + 1), it is not possible to split the supplies evenly between the power feeds. As a result, if one power feed fails, the whole system can go down. In either type of redundancy, if a single power supply fails, the system is unaffected by the loss of a single supply.

The DC power supply does not have an on/off switch. You can control the power from the rack switch or the DC power source.

VIPRION 4400 Series DC power supply

Installing a DC power supply

About the fan tray

The VIPRION® 4400 Series platform has a removable fan tray that is designed to maintain airflow throughout the chassis. You can change or replace the fan tray as part of the routine maintenance of the unit, or in the event of a fan failure. The fans in the fan tray run constantly while the unit is on. Over time, the fans can wear out, requiring you to replace the fan tray.

Fan tray in the platform

Replacing the fan tray

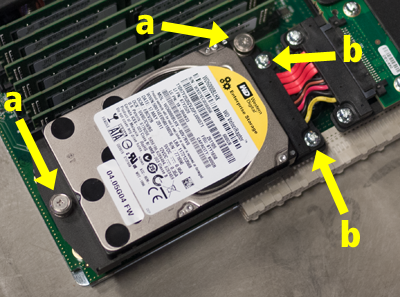

About the storage drives

By default, VIPRION® B4000 blades contain one storage drive. You can remove the drive from the blade only if your company's security requirements necessitate it when performing a Return Material Authorization (RMA) on the platform.

Replacing a storage drive assembly on a B4300 blade

About the front bezel (with LCD component)

The LCD component on the front bezel enables you to access several functions associated with the platform, such as configuring the management port for the system.